- Hogar

-

Productos

-

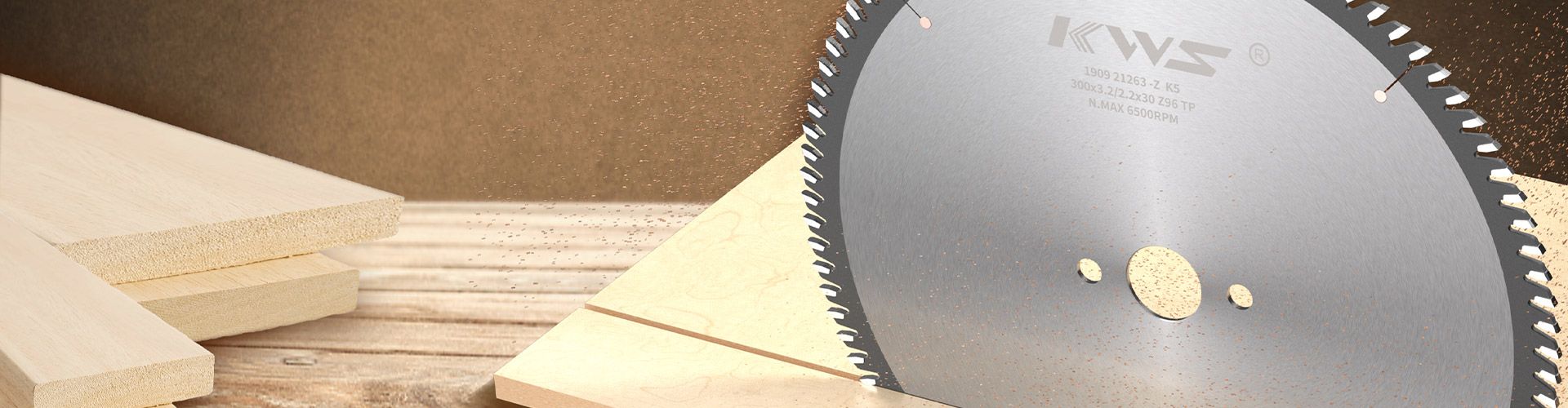

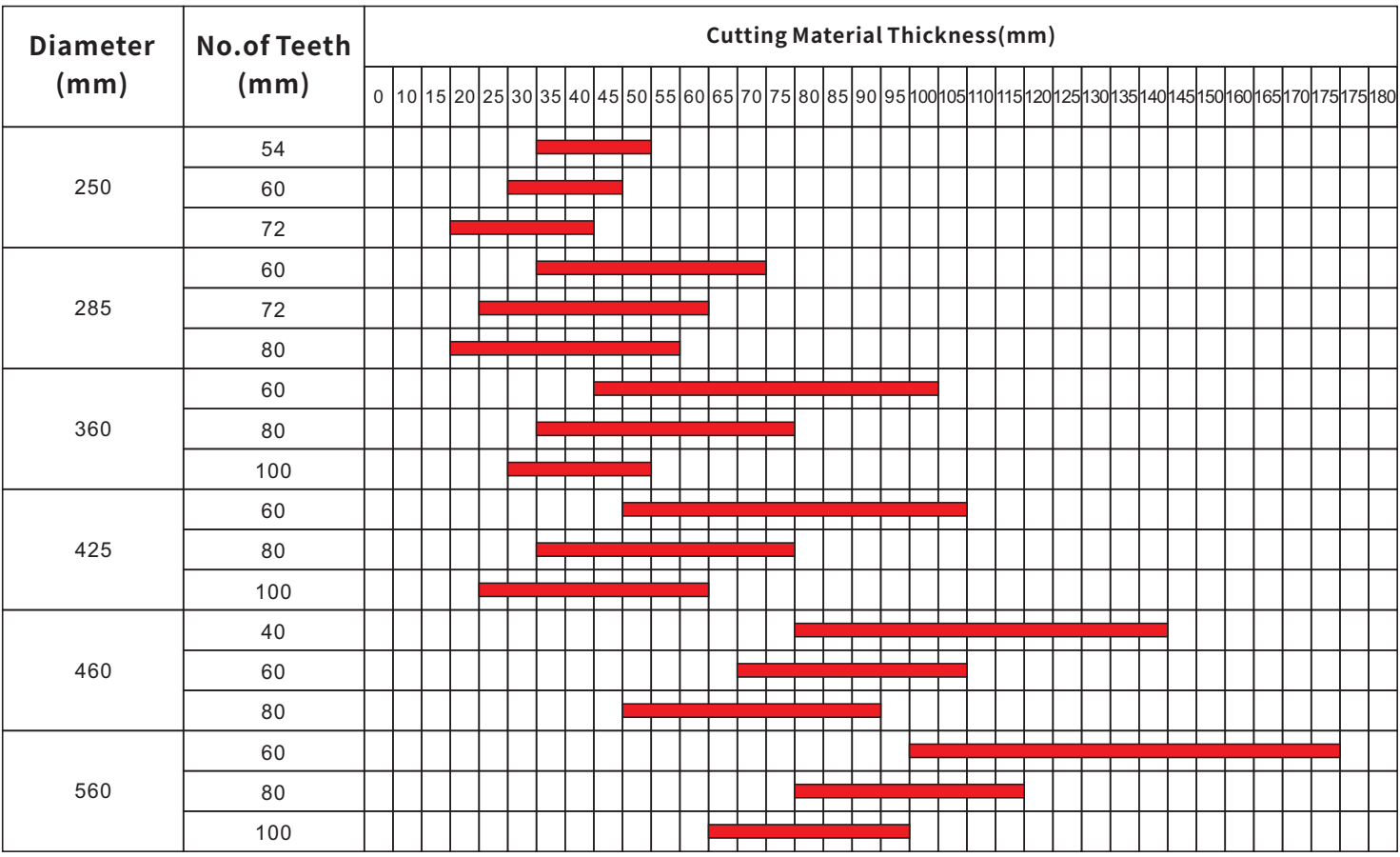

Hoja de sierra para cortar madera

Hoja de sierra para cortar madera

-

Sierra fría para cortar acero

Sierra fría para cortar acero

-

Hoja de sierra para cortar aluminio

Hoja de sierra para cortar aluminio

-

Cortador de prefresado PCD

Cortador de prefresado PCD

-

Broca

Broca

-

Bit de enrutador

Bit de enrutador

-

Cabezales cuchillas

Cabezales cuchillas

-

Cuchillos cepilladores

Cuchillos cepilladores

-

Portabrocas de pinza

Portabrocas de pinza

-

Muela de diamante

Muela de diamante

- Hoja de sierra universal

- Hoja de sierra para cantos

- Hoja de sierra para dimensionamiento de paneles

- Hoja de sierra de puntuación ajustable

- Hoja de sierra de puntuación cónica

- Hoja de sierra circular Milti con rastrillos

- Hoja de sierra para ranurar

- Hoja de sierra para una sola viruta

- Hoja de sierra de corte fino

- Sierra en frío para corte de acero de medio y bajo carbono

- Sierra fría para corte de acero con alto contenido de carbono

- Sierra fría para corte de tuberías

- Sierra fría para corte de acero inoxidable

- Sierra fría para dispositivo manual

- Sierra TCT para corte de aluminio

- sierra voladora

- Broca para ensalada

- Broca de agujero cuadrado

- Cortador morsiting

- Taladro de pasador

- Broca de espiga de servicio súper

- Broca para bisagra

- Broca escalonada

- Fresa para aluminio

- Broca de sujeción pasante

- Bit de grabado

- Bit de embutir

- Cortador de paneles

- Cortador de juntas de dedo

- Cortador redondo de 1/4 de esquina

- Cortador semicircular

- Cortador de ranuras

- Cortador de marco de puerta

- Cortador de tablones de puerta

- Cortador de bandas de borde

- Cortador de espiga

- Bloque de corte helicoidal

- Cortador de Ranurado Ajustable

- Cortador de puerta de gabinete

- Cortador de cepilladora con hoja reemplazable

- Cuchillas cepilladoras tipo HSS

- Cuchillas cepilladoras con incrustaciones de carburo

- Insertos de carburo reversibles

- Cuchilla raspadora para enchapadora de cantos

-

- Sobre nosotros

- Descargar

- Únete a nosotros

- Contactos